Dredging operations are vital for maintaining waterways, reclaiming land, and extracting resources. At the heart of these operations lies the floating dredging hose, a crucial component responsible for transporting dredged material efficiently. However, choosing the right floating dredging hose can be challenging. This guide addresses common questions and concerns, providing the information you need to select the optimal hose for your specific dredging project.

Customer Pain Points

Confusion Over Material Selection: Knowing which material best suits the dredging environment and the type of material being transported.

Determining the Correct Hose Length: Accurately calculating the required hose length to avoid inefficiencies and potential safety hazards.

Understanding the Hose’s Limitations: Recognizing the operational constraints and ensuring the hose is compatible with the dredging equipment and environmental conditions.

Durability and Longevity Concerns: Worrying about the hose’s lifespan, especially in harsh conditions, and the potential for costly replacements

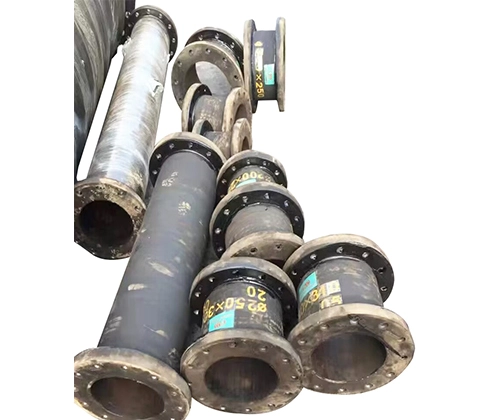

Floating dredging hoses are specifically engineered to transport dredged materials, such as sand, gravel, silt, and other sediments, from the dredging site to a designated disposal area or processing facility. Their primary function is to provide a flexible and buoyant conduit for the efficient and continuous transfer of these materials. Unlike rigid pipes, these hoses can navigate uneven terrain and adapt to the movement of the water surface.

Key applications of floating dredging hoses include

Channel Maintenance: Maintaining navigable waterways by removing accumulated sediment.

Land Reclamation: Creating new land areas by depositing dredged material.

Mining Operations: Extracting valuable resources from underwater deposits.

Environmental Remediation: Removing contaminated sediments from polluted areas.

Beach Nourishment: Replenishing eroded beaches with dredged sand.

The selection of materials for floating dredging hoses is critical to ensure durability, flexibility, and resistance to abrasion, corrosion, and other environmental factors. Here’s a breakdown of common materials:

The following table summarizes the key properties of each material:

Material

| Abrasion Resistance | Chemical Resistance | Flexibility | UV Resistance | Cost | Common Applications |

Natural Rubber | Excellent | Fair | Excellent | Poor | Moderate | Dredging sand and gravel, general-purpose dredging |

Synthetic Rubber | Good | Good | Good | Good | Moderate | Dredging in chemically aggressive environments, handling oily sediments |

Polyureth -ane | Exceptional | Good | Fair | Fair | High | Dredging highly abrasive materials like rocks and heavy minerals |

PVC | Fair | Good | Fair | Good | Low | Light-duty dredging, applications with minimal abrasion |

HDPE (Floatatio-n) | Good | Excellent | Rigid | Excellent | Moderate | Providing buoyancy and protection to the hose; not in direct contact with dredged material |

How to Determine the Appropriate Length of a Floating Dredging Hose for the Project ?

Determining the correct length of a floating dredging hose is crucial for operational efficiency and safety. Too short, and the hose will be under strain, potentially leading to damage or failure. Too long, and it can create excessive drag, reduce pumping efficiency, and pose a navigation hazard.

Factors to consider when calculating the required hose length:

Distance Between Dredge and Discharge Point: This is the most obvious factor. Measure the distance accurately, accounting for any curves or bends in the route.

Water Depth: The hose needs sufficient length to reach the bottom of the dredging area.

Tidal Variations: Account for changes in water level due to tides. Add extra length to accommodate the highest tide.

Dredge Movement: Consider the dredge’s range of movement. The hose should be long enough to allow the dredge to move freely within its designated area.

Slack and Sag: Add extra length to allow for slack and sag in the hose. A general rule of thumb is to add 10-20% to the straight-line distance.

Submerged vs. Floating Length: Consider the proportion of the hose that will be submerged. Submerged hose needs less added slack.

Example Calculation

Let’s say the distance between the dredge and the discharge point is 500 meters, the maximum water depth is 10 meters, and the tidal variation is 2 meters. The dredge is expected to move within a 50-meter radius.

Straight-Line Distance: 500 meters

Water Depth: 10 meters (negligible compared to the overall length)

Tidal Variation: 2 meters (negligible compared to the overall length)

Dredge Movement: Add the radius of movement: 50 meters

Total Length: 500 + 50 = 550 meters

Slack and Sag (15%): 550 * 0.15 = 82.5 meters

Final Estimated Length: 550 + 82.5 = 632.5 meters

Therefore, you would need approximately 632.5 meters of floating rubber hose for this dredging project. It’s always better to err on the side of caution and add a bit of extra length to ensure flexibility and prevent strain.

Choosing the right floating dredging hose requires careful consideration of various factors, including material properties, hose length, and application requirements. By understanding these key aspects and addressing common pain points, you can ensure optimal dredging performance, minimize downtime, and maximize the lifespan of your equipment. Contact qualified dredging hose suppliers like Yonghong for expert advice and tailored solutions to meet your specific needs.

Other Dredging Hoses and Sealing Elements You May Also Like

- Maximizing Efficiency and Safety in Tailings Dredging

- Regional Differences Impact on Dredging Rubber Hose Selection

- Sewer Seal Ring: Securing Urban Infrastructure

- Meeting the Demands of Modern Dredging:High-Performance Rubber Hoses

- Custom Engineered Dredge Hose Solutions for Bulk Purchases

- A Repo of China Dredging Technology & Equipment Expo 2025

English

English