Marine rubber seals are a type of elastic sealing element specifically used in marine and ship environments. They are primarily made of synthetic rubber materials that are corrosion-resistant, aging-resistant, sea water-resistant, and highly elastic. These seals are used to fill the gaps in equipment joints, preventing the leakage of liquids or gases under conditions of high pressure, high humidity, and dynamic loads. These seals can bear pressure differences and possess good recovery and durability, making them indispensable basic components in marine systems.

Common Material Types

To adapt to the complexity of the marine environment, marine rubber seals are usually made from the following materials:

Neoprene (CR): Possesses good resistance to sea water corrosion and ozone, suitable for hull doors, watertight windows, and other parts;

Fluororubber (FKM): Resistant to high temperatures, oil, and chemical corrosion, suitable for engines and fuel line seals;

Silicone rubber (VMQ): Adapts to extreme temperature differences, suitable for electronic equipment and communication compartments;

EPDM rubber: Aging-resistant, UV-resistant, and sea water-resistant, commonly used for deck and window seals on ships.

The choice of material depends on the physical and chemical environment of the seal's location, as well as the operating temperature and pressure range.

Main Types and Uses

Marine rubber seals come in many varieties, broadly divided by structure and use into the following types:

O-rings: The most common rubber seals, used in bearings, pump bodies, valves, and other dynamic or static joints.

Lip seals (oil seals): Used for rotary shaft sealing, such as in marine engines and propeller systems.

Door and window seals: Installed on hatch doors, watertight windows, and deck openings to prevent wind, rain, and seawater intrusion.

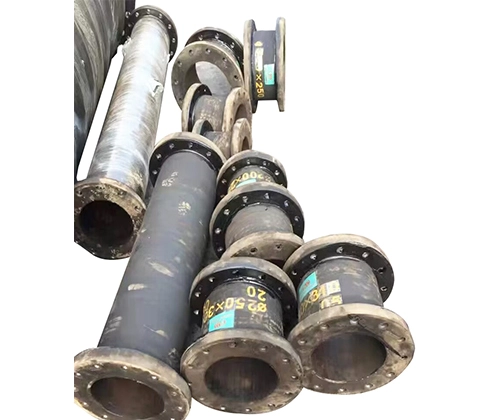

Corrugated gaskets: Used for flange pipe connections, enduring high pressure and temperature to ensure tight system closure.

Hatch cover seals: Specially designed for large cargo ship hatches to ensure no water enters the cargo hold under harsh sea conditions.

These seals not only maintain the tightness of equipment but also cushion mechanical vibrations, reduce noise, and extend the lifespan of the entire machine.

Wide Range of Applications

Marine rubber seals are widely used in:

Commercial ships (such as cargo ships, oil tankers, container ships): Used in hydraulic systems, fuel systems, and cargo compartment door seals.

Military vessels and submarines: Require very high sealing standards to prevent water pressure intrusion and airtight leaks.

Offshore platforms (such as oil drilling platforms): Used in equipment compartments, underwater pipelines, and safety valves.

Port facilities: Including rubber fender seals, floating bridge structure seals, etc..

Deep-sea exploration equipment and underwater robots: Require extremely high material pressure resistance and elasticity.

Although seemingly small, marine rubber seals are vital barriers to the safe operation of marine equipment. From large warships to precision submersibles, from everyday cargo ships to deep-sea energy platforms, they all rely on the stable support of these critical components. With continuous advancements in marine engineering technology, seals are also upgrading, providing higher strength, better durability, and greater intelligence to ensure the steady development of the marine economy.

- The Role of Sewer Seal Rings in Marine Pollution Prevention

- Maintenance and Lifespan Management of Dredge Rubber Hoses

- Optimizing Sand Dredging in Australia: The Role of Custom Rubber Dredge Hoses

- Maximizing Efficiency and Safety in Tailings Dredging

- Smart Hose Systems for Amphibious Dredgers

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

English

English