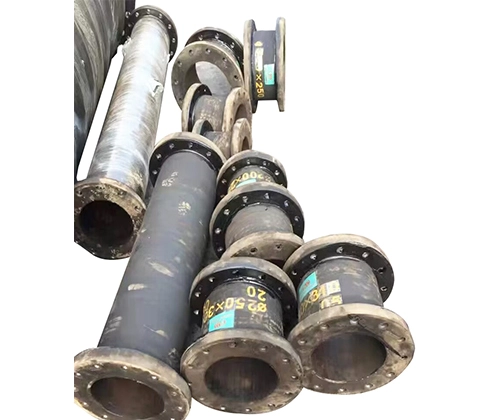

What is Floating dredging hose?

A floating dredging hose is a flexible pipe designed for dredging operations where its primary function is to transport material (e.g. silt, sand, gravel, etc.) excavated from the bottom of the water. The self floating rubber hose has a characteristic that allows it to float on the surface of the water, thus reducing the resistance of the water flow to the pipe and increasing the flexibility and efficiency of the operation.

| Self-floating design | Abrasion and corrosion resistant | Easy to connect |

| When the inner lumen is filled with medium, the entire body of the tube (excluding end fittings) carries a buoyant material that ensures that it floats on the surface of the water. | Highly abrasion-resistant rubber layers and reinforcements are used for harsh marine environments, including armor flex hose options | A variety of end fittings (e.g. flanges, snap locks, clamps) are provided for easy installation and connection, sourced from reputable dredge rubber hose manufacturers. |

Main application scenarios

| Harbor and waterway maintenance | River and Lake Dredging |

| Used to remove silt and sediment from harbors and waterways to ensure safe passage of ships. | Used to remove silt from river beds and lakes to maintain water depth and improve water flow. |

| (High Demand) | ( Medium needs) |

| Coastal Engineering | Land Reclamation |

| Used in coastal engineering to control erosion, manage sediment transport and maintain navigation channels. | Used in land reclamation projects to pump sediment from a water body to a designated area to open up new land for construction or environmental restoration. |

| (High Demand) | ( Medium needs) |

| Offshore oil and gas industry | Mineral mining |

| Used for pipeline installation and maintenance in offshore oil and gas operations, as well as for subsea reservoirs. | In mineral mining, especially alluvial mining, used to extract sands, gravels and minerals from riverbed or seabed sediments. |

| (High Demand) | ( Medium needs) |

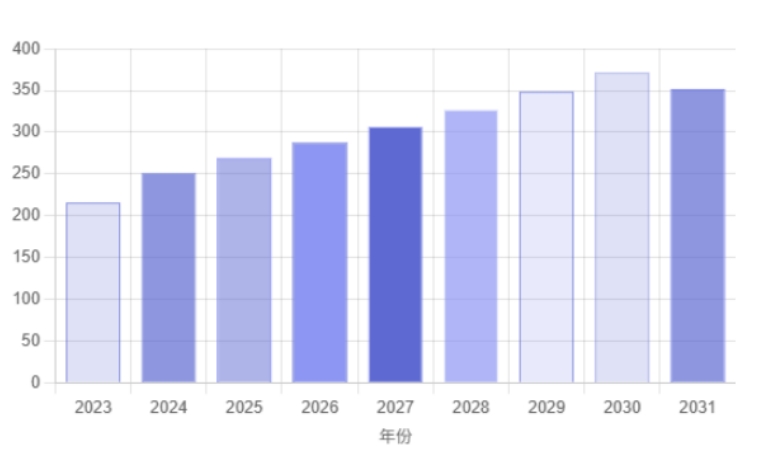

Global Dredging Industry Market Size and Growth Trends

According to QYResearch, the global dredging market reached USD 25.14 billion in 2024 and is expected to grow to USD 35.2 billion by 2031, at a CAGR of 5%. This growth mainly stems from the surge in demand for projects such as port expansion, land reclamation, and marine energy development, etc. Floating dredging hoses, as the core equipment for transporting materials such as sediment and ore, directly determine the project efficiency and cost by their performance.

Market Size Forecast USD Billion

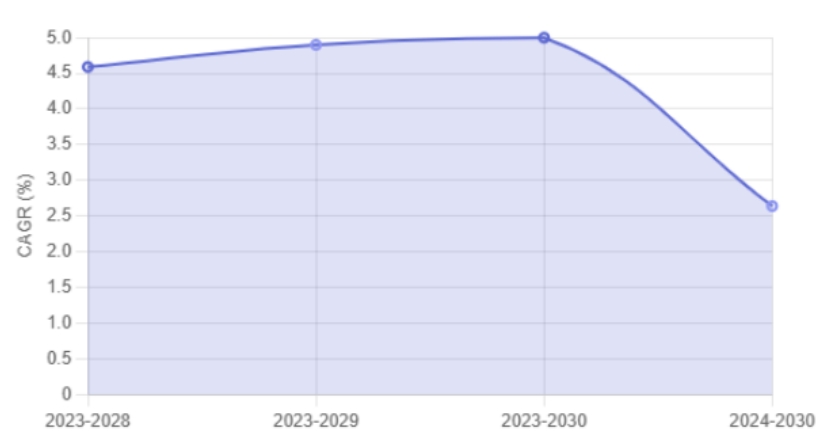

Compound Annual Growth Rate (CAGR)

Key Data Points

Global dredging market size was approximately USD 25.14 billion in 2024

It is expected to reach USD 35.2 billion by 2031, at a compound annual growth rate (CAGR) of 5.0%

Asia-Pacific is the largest dredging market in the world, holding approximately 50% of the market share

Key drivers include infrastructure development, urbanization, and technological advancements for environmental protection

Users' core requirements for floating hose products

| Safety and Reliability | Durability and Life | Flexibility and Adaptability |

| Users demand a high level of safety from floating hoses, especially in the marine environment where the hose needs to withstand extreme conditions (e.g. high pressure, salt water, UV rays, etc.). | Users expect floating hoses to have a long service life, usually requiring a design life of 20 years or more, with some high-end products even reaching 25 years. | Floating hoses need to be flexible and able to adapt to complex coiling and stretching operations, often supplied by leading dredge hose suppliers. |

| Environmental Protection and Sustainability | Customization and Intelligence | Cost Effectiveness and Ease of Maintenance |

| As the goal of “carbon neutrality” advances, there is an increased interest in environmentally friendly materials and recyclable products. | Users' demand for product customization is growing, especially in different application scenarios, where hose sizes, flange types, connections, etc. can be adjusted according to customer needs. | Users want to reduce product costs and improve maintenance efficiency while maintaining performance. |

Six Technical Challenges of Floating Dredging Hose

1.Insufficient pressure resistance: ordinary hose is easy to burst in high-pressure sediment transportation, Chinese standard GB/T 37221 requires rated pressure ≥ 1.5MPa, but some products only up to 0.8MPa.

2. Short wear life: coral, weathered rock and other abrasive materials lead to hose annual loss rate of up to 30%.

3. Complicated and time-consuming installation: the traditional hose bending radius needs to be ≥ 10 times the outer diameter, and special ships are required to assist.

4. Poor buoyancy stability: 20% of the hoses are not suitable for use in the sea.

5. Easy debonding of joints: 57% of breakage occurs in the area of 570-672mm from the flange under tensile load.

6. High maintenance cost: single replacement cost is 8-12% of the total project budget

As global dredging projects expand into deep sea and complex geological environments, the technological threshold of floating hoses will continue to rise. Choosing products with both pressure resistance and quick maintenance capability will become the key to controlling costs and improving project efficiency. Consult with Yonghong Marine Rubber today to get the latest hose technology solutions and quotes for 2025!

Popular Search Terms at YONGHONG

dredge rubber hose manufacturers in the USA

- Mastering Dredging with High-Performance Hoses

- Armored Self-Floating Rubber Pipe: A Comprehensive Overview

- Dredging Hose Selection Questionnaire

- Custom Engineered Dredge Hose Solutions for Bulk Purchases

- Optimizing Sand Dredging in Australia: The Role of Custom Rubber Dredge Hoses

- Top Dredge Hose Manufacturers in China

English

English