The China (Shenzhen) Dredging Technology & Equipment Expo 2025 took place at the Shenzhen Convention & Exhibition Center (Futian) on September 2025. As a member of the dredging community, we followed the Expo’s coverage and discussions closely. The event underscored several trends that were particularly relevant to dredging hose specifiers and project engineers — especially the technologies and suppliers showcased in the Dredging Materials & Equipment Zone (Exhibit Area B).

(image reference from https://ysln.ycwb.com/content/2023-07/13/content_52071224.html)

What the Expo emphasized (recap)?

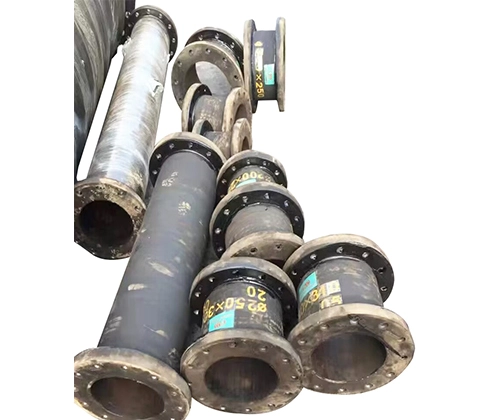

The Expo framed dredging as an increasingly central tool for coastal infrastructure, port development and environmental remediation. Presentations and booths highlighted how integrated systems — including cutter-suction dredgers, pumps, floating pipelines and material handling solutions — were being adapted for larger reclamation and remediation assignments. Exhibit Area B collected the specialized components that determine on-site reliability: pumps and valves, floating pipeline materials, dredging pumps and control systems, abrasion-resistant linings, and heavy-duty couplings. For those of us concerned with slurry transport, seeing these items displayed together made one point very clear: hose performance cannot be judged in isolation.

Key takeaways for dredging hose selection:

Based on the expo’s themes and the technical briefings shared by multiple exhibitors, three practical implications stood out:

System compatibility drove real performance. Presenters made it evident that hoses performed best when selected as part of a matched system — pump curves, float placement, pipeline layout and seabed conditions all influenced hose wear and hydraulic efficiency. This is especially true for floating dredging hoses, which require precise integration with floating pipeline systems.

Material engineering mattered more in long-run projects. In reclamation and continuous fill works, abrasion-resistant inner liners, multi-layer reinforcement, and robust end fittings reduced unplanned replacements and maintenance windows. Suppliers such as leading dredge hose suppliers demonstrated innovative materials that extend hose lifespan.

Lifecycle thinking was becoming mainstream. Several suppliers demonstrated products and service models focused on predictable maintenance cycles, modular repairs and easier inspection — all factors that reduce total cost of ownership over long campaigns. This approach aligns with the demands faced by dredge pipe suppliers working on extensive dredging projects.

How dredging hose manufacturers and buyers responded?

Following the Expo, discussions among contractors and equipment suppliers showed a shift toward specifying not just a hose type, but a hose-centric subsystem: pump compatibility checks, standardized coupling interfaces, and inspection access points were being integrated into procurement specs. This marked a movement from “product buy” to “system buy” — a change that favored hoses designed for inspectability, repairability and long service life. For example, self floating hose solutions gained attention due to their adaptability and ease of use in marine environments.

Where YH Rubber Hose fit into the picture?

Drawing on the Expo highlights, YH Rubber Hose positioned its dredging range to match these evolving expectations. Our dredging hoses — including self-floating, suction and discharge types — were designed with the following priorities in mind:

System-level compatibility: hose options with end fittings and coupling interfaces compatible with common cutter-suction dredger outputs and floating pipeline transitions.

Durability: abrasion-resistant inner liners and optional armored layers for projects involving coarse sediments or long-distance discharge.

Maintainability: features that support modular inspection and predictable replacement cycles to minimize downtime during extended campaigns.

These attributes reflected the Expo’s emphasis on integrated, lifecycle-oriented procurement.

Practical advice drawn from the Expo

From the conversations and technical briefings at the Expo, practical next steps for engineering teams and procurement leads were clear:

Validate pump-to-hose compatibility early in design to reduce wear and energy loss.

Prioritize abrasion rating and liner options where sand and gravel content is high.

Incorporate spare modules and inspection points into logistics planning for long reclamation projects.

If your upcoming project involves reclamation, long-distance sand transport, or continuous dredging cycles, we can help evaluate hose compatibility and lifetime cost implications. Contact our engineering team for product datasheets, pump-to-hose checklists, and case-based recommendations at sales@yhrubberhose.com

- Marine Fender Suppliers: The Invisible Guardians of Port Safety

- Situation and Development of the Dredge Rubber Hose

- Why Do Rubber Fenders Come in Different Colors?

- Top Dredge Hose Manufacturers in China

- Why Rubber Fenders Are Essential Devices For Ships?

- Product Characteristics of Yonghong Sealing Rings for Ships

English

English