When we think of dredging—the process of (re)moving sediments for mining, navigation, or environmental remediation—we often focus on the massive ships and their powerful cutters. However, the most critical part of a hydraulic dredge's operation is its "circulatory system": the pipeline. While people often use the terms "dredging pipe" and "dredging hose" interchangeably, they serve very different functions in the challenging environment of underwater construction.

The Dredging Pipe: The Rigid Highway

In dredging terminology, the "pipeline" or "pipe" usually refers to the rigid sections of the transport system. Hydraulic dredges, such as pipeline dredges, work by mixing sediment with water to create a slurry (typically 10% to 20% solids by weight) and pumping it to a destination.

• Characteristics: These pipes are often made of steel or high-density plastic to withstand the high pressure of the pumps and the abrasive nature of heavy sediments.

• Role: They form the long-distance "highway" that carries slurry from the dredging site to the placement area.

• Challenges: Constructing these pipelines requires significant mobilization effort and cost. Once laid, they can become physical barriers to other water traffic.

The Dredging Hose: The Flexible Joint

While the sources often use the collective term "pipeline," the reality of working on water requires flexibility. Floating dredging equipment does not stay perfectly still; it moves erratically in both horizontal and vertical directions due to waves and operational shifts.

• Why Hoses? A completely rigid steel pipe would snap under the stress of a moving dredge. This is where the dredging hose (or flexible joint) comes in.

• Role: Hoses act as the "tendons" and "ligaments" of the system. They are used to connect the moving dredge to the fixed pipeline, or to allow the pipeline to bend around corners and over uneven sea floors.

• Usage in Hopper Dredges: Hopper dredges also use flexible suction arms (which include reinforced hoses) to suck up sediment while the ship is in motion.

A Complementary System

In the sources, these components are combined into what is known as a Hydraulic Transport System. This "closed system" is highly efficient because it moves sediment directly from the source to the placement site without the need for secondary handling or "rehandling".

Feature | Dredging Pipe (Rigid) | Dredging Hose (Flexible) |

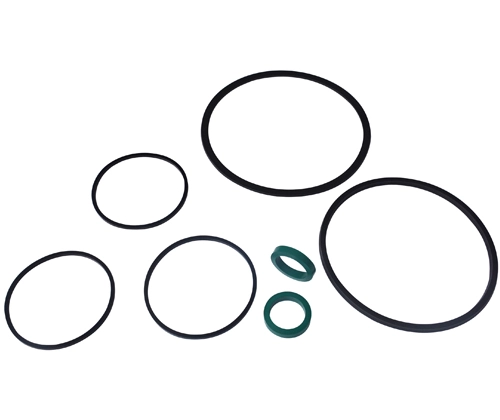

Primary Material | Steel or Rigid Plastic | Rubber with internal reinforcement |

Main Function | Long-distance transport of slurry | Absorbing movement and vibration |

Mobility | Low; requires ancillary vessels to move | High; adapts to dredge drift |

Location | Long stretches on water or land | Connections at the dredge or joints |

While they are part of the same "pipeline," the pipe provides the strength and distance, while the hose provides the necessary flexibility to survive the "erratic" movements of the sea. Together, they allow dredging projects to move millions of cubic yards of sediment safely and efficiently to build beaches, clear shipping channels, and restore environments.

English

English