Efficient and safe tailings dredging is a critical activity for the mining industry. Proper handling of tailings slurries affects site safety, processing continuity, regulatory compliance, and long‑term mine closure plans. Failures in dredging systems can cause costly downtime, environmental incidents, and safety hazards for workers and communities near impoundments.

Tailings dredging presents specific challenges: slurries are often highly abrasive, variable in solids concentration and particle size, and can be chemically reactive (acidic, alkaline, or containing sulfides and corrosive reagents). Solids settling, blockages, and fluctuating operating pressures increase mechanical stress on hoses and couplings. At the same time, stringent environmental regulations demand leak‑free systems, contamination control, and robust reporting and monitoring.

Custom rubber dredge hoses are a key component in addressing these challenges. Properly engineered hoses help maintain pump efficiency, resist rapid internal wear, withstand chemical exposure, and reduce the likelihood of catastrophic failures that could create environmental or safety incidents. For bulk purchasers—mining companies, tailings management contractors, and EPC firms—selecting the right hose solution is a strategic decision that affects project risk and lifecycle cost.

This article explores essential considerations for bulk purchasers of rubber dredge hoses for tailings dredging applications.

Critical selection criteria

- Abrasion resistance: Prioritize hose constructions with wear‑resistant inner liners and proven compound formulations. High silica content and sharp particles accelerate erosion; replaceable wear sleeves or sacrificial liners extend service life in abrasive slurries.

- Chemical compatibility: Confirm the rubber compound resists the specific chemistry of your slurry—acids, alkalis, solvents, or oxidizing agents. Request chemical compatibility data and, where necessary, custom compound formulations.

- Pressure, vacuum and flexibility: Match hose wall thickness, reinforcement (textile/steel spirals) and diameter to pump capabilities and pipeline length. Consider flexibility needs for deployment and handling, and ensure negative pressure (suction) ratings if used on dredge inlets.

- Anti‑clogging and hydraulic efficiency: Larger internal diameters, smooth bore finishes, and optimized internal profiles reduce head loss and blockages, improving pump efficiency and lowering energy consumption.

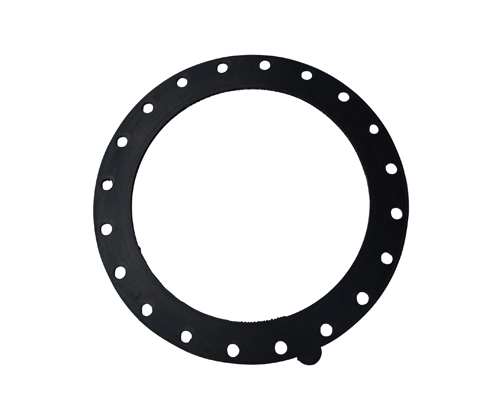

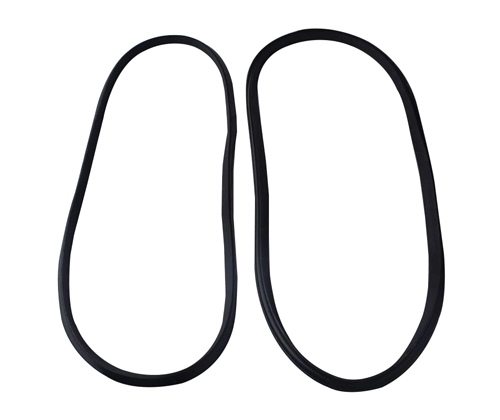

- Couplings and joint integrity: Use heavy‑duty, corrosion‑resistant couplings designed for tailings service. Quick‑release or bolted flanges with proper seals and emergency clamp options simplify maintenance and reduce leak risk.

- Testing, certification and traceability: Require hydrostatic and abrasion testing, material certificates, and third‑party validation where applicable. Batch traceability and serial numbering support maintenance records and regulatory audits.

Procurement and lifecycle management

- Supplier capability: Work with manufacturers experienced in mining applications who can provide site trials, material testing, and custom design support.

- Spares, maintenance and monitoring: Stock modular hose sections, couplings and repair kits on site. Implement routine inspection regimes and integrate pressure/flow monitoring to detect wear or impending failure.

- Total cost of ownership: Evaluate expected lifespan, maintenance frequency and downtime risk alongside unit price. Higher‑grade hoses often deliver lower cost per cubic meter pumped.

- Environmental and disposal considerations: Choose low‑leach compounds where required and discuss end‑of‑life disposal or recycling options with suppliers to meet environmental commitments.

Conclusion

Tailings dredging demands hose systems engineered for abrasive, chemically active slurries and variable operating conditions. Bulk purchasers should prioritize site‑specific specification, verified testing, strong supplier support and lifecycle planning to maximize efficiency and safety while minimizing environmental and financial risk. Consulting with experienced hose manufacturers early in project planning ensures the right balance of performance, durability and regulatory compliance.

- A Repo of China Dredging Technology & Equipment Expo 2025

- Dredging Hose Selection Questionnaire

- The Advantages of Zhenjiang Dredging Rubber Hose

- Self-Floating Dredge Hose: A Competent Assistant in Hydraulic Engineering

- Top Dredging Hose Manufacturers in the USA

- Unleash the Power of Your Projects with Advanced Sand Suction and Discharge Rubber Hoses

English

English