Floating hoses are a critical component in modern dredging operations — especially for capital dredging, port construction, land reclamation, and deepwater sediment transport. The right floating hose not only improves efficiency and safety, but also significantly reduces downtime and lifecycle costs.

This guide walks you through the key factors you must understand before choosing floating hoses that will perform reliably across your dredging project.

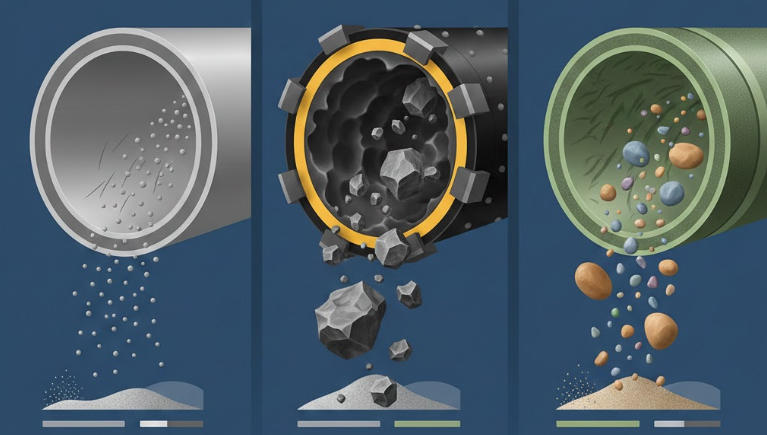

Know What You Are Pumping

The first step in selecting the right floating hose is understanding the material you’ll be transporting. Different dredging media have vastly different impacts on hose performance.

Fine sand & silt: Moderate abrasion

Gravel & coarse particles: High abrasion, requires thicker linings

Mixed sediment: Demands balanced abrasion resistance and flexibility

Coarse or highly abrasive materials call for hoses with enhanced wear resistance, such as heavy-duty floating hoses or armored floating hoses. Choosing a hose suited to your slurry type ensures longer service life and lower maintenance costs.

Diameter and Length

Two physical dimensions directly influence dredging efficiency:

Diameter

Larger diameter = higher volume throughput

But excessive diameter may increase hose weight and reduce flexibility

Length

Must be sufficient to reach your discharge point

Too long can increase resistance and reduce pump efficiency

A careful balance between diameter, flow rate, pump capacity, and layout is essential for performance optimization.

Working Pressure and Safety Margin

Floating hoses must withstand internal pressures generated by dredging pumps and external dynamic forces such as waves, tides, and vessel movement.

For rubber floating hoses, the burst pressure is strictly defined by industry standards (specifically GMPHOM 2009 for offshore oil) based on a safety factor relative to the working pressure.

Key Technical Standards

GMPHOM 2009 (OCIMF): The global standard for offshore floating hoses. It mandates a 5:1 safety factor. If you are sourcing for oil & gas, this certification is mandatory.

Surge Pressure: Hoses are also often tested to withstand temporary surges of 2.5x the working pressure without damage.

Dredging Hoses: Non-oil dredging hoses often use a lower 4:1 safety factor.

Selecting a hose with appropriate pressure ratings helps prevent catastrophic failures and supports operational safety under heavy load conditions.

Rated Working Pressure (RWP) | Minimum Burst Pressure | Application Scenario |

15 bar (217 PSI) | 75 bar (1,088 PSI) | Standard offshore oil transfer |

19 bar (275 PSI) | 95 bar (1,378 PSI) | High-pressure transfer |

21 bar (305 PSI) | 105 bar (1,523 PSI) | Extreme pressure/Surge risk |

10 bar (145 PSI) | 40 bar (580 PSI) | Common for dredging (Safety Factor 4:1) |

Flexibility & Bending Radius

Floating hoses operate on moving water surfaces and often need to adjust to changing angles, currents, and vessel positions.

Bending radius: The minimum curve the hose can withstand without kinking or structural damage.

Too stiff → Limited maneuverability

Too flexible → Risk of collapse under pressure

Ensure hoses have an adequate bending radius suitable for your dredger’s working area and floating pipeline layout.

Flotation Performance

The primary purpose of a floating hose is to stay buoyant while carrying heavy slurry. Key flotation considerations include:

High buoyancy: Enough to keep the hose above water even under load

Closed-cell foam or integrated float materials: Prevent water absorption

Stable buoyancy under waves and currents: Prevent sagging or sinking

Without proper flotation performance, hoses can drag on the seabed, leading to premature abrasion or failure.

Environmental & Weather Resistance

Marine environments are notoriously harsh. Floating hoses must withstand:

UV exposure

Saltwater corrosion

Temperature variations

Ozone and weather aging

High-quality hoses use specialized compounds and outer covers that remain durable in these conditions, preserving operational integrity throughout the project duration.

End Connections & Compatibility

Floating hoses are part of a larger dredging system involving pumps, pipelines, and manifolds. End connections must be:

Compatible with your dredger’s flange types

Durable under pressure cycling

Easy to install and seal

Custom connections or adapters may be needed for specific systems — always clarify this with the supplier before ordering.

Standards, Certification & Quality Assurance

Before finalizing any purchase, check whether the hose complies with recognized standards such as:

ISO quality and material specifications

Third-party inspection reports

Documented pressure and burst test results

Certified hoses provide a measurable guarantee of performance and safety, which is critical for CAPEX-level dredging investments.

Working with a supplier who understands dredging system integration — not just hose manufacturing — will save time and reduce risk.

Summary: What Makes a Good Floating Hose

Factor | Why It Matters |

Material & lining | Affects abrasion resistance |

Diameter & length | Impacts flow and pump efficiency |

Pressure rating | Ensures safety and reliability |

Flexibility | Reduces kinking and supports dynamic movements |

Flotation capability | Prevents seabed contact and wear |

Environmental resistance | Ensures long service life |

Standards & testing | Provides quality assurance |

Manufacturer expertise | Supports system compatibility |

Choosing the right floating hose is more than picking a product from a catalog — it's about understanding the demands of your dredging environment, slurry type, operational pressure, and vessel system. A thoughtfully selected hose improves operational efficiency, safety, and lifecycle value.

For complex or large-scale dredging works, consider consulting technical experts or experienced suppliers who can tailor hose solutions to your actual working conditions and equipment specifications.

- Understanding the Regional Distribution of Dredging Rubber Hose in China

- Common Failure Modes in Dredging Rubber Hoses

- Understanding Materials, Length, and Applications for Optimal Dredging Performance

- What Makes a High-Quality Dredging Rubber Hose?

- Top Dredge Hose Manufacturers in China

- What Are Marine Fenders and Their Purposes

English

English