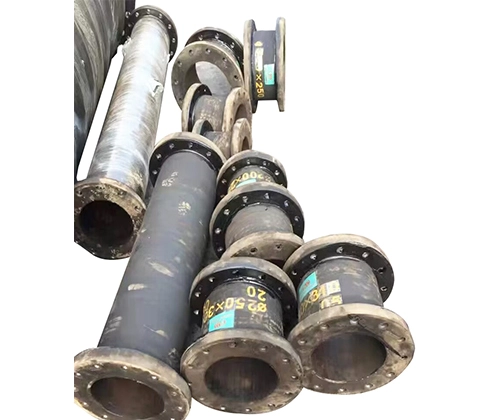

In modern dredging projects, the efficiency and reliability of material transport systems are often determined by the performance of the dredging pipeline — and at the heart of that system lies the rubber hose assembly. Far from being a single consumable part, a well-designed hose system functions as an integrated network that ensures continuous, safe, and efficient slurry transfer under highly variable marine conditions.

Understanding the “Total Hose Solution” Concept

The concept of a Total Hose Solution has emerged as a new standard in the global dredging industry. Instead of treating each hose — suction, discharge, floating, or armored — as a separate item, leading contractors and equipment manufacturers now emphasize system integration. According to guidance from PIANC and CEDA, a complete hose system should be designed as part of the dredger’s overall hydraulic and structural configuration, accounting for flow velocity, sediment characteristics, and dynamic loads from tides and waves.

In practice, this means that hose assemblies are no longer selected merely by diameter or pressure rating. They must be engineered to work in harmony with pumps, couplings, floats, and dredger operating parameters, ensuring both operational safety and long-term cost efficiency. This also involves collaboration with a trusted sealing element company to ensure optimal sealing solutions and integration with ship sealing systems.

Experience from Real-World Applications

At YH Rubber Hose, our experience with large-scale reclamation and port dredging projects has shown that a total solution approach significantly extends service life and reduces maintenance downtime. For example:

Customized lining compounds are selected based on sediment abrasiveness — fine sand, coral fragments, or silt require different rubber formulations.

Reinforcement layers are optimized for flexibility or rigidity depending on the bending radius at the suction ladder or discharge pontoon.

Integrated float and hose systems improve stability in offshore applications, reducing fatigue at connection points — one of the most common failure areas in traditional setups.

We are not only one of the top dredge pipe suppliers to provide comprehensive pipeline solutions, but also one of the leading marine fender China manufacturers to protect marine infrastructure during dredging operations.

System Design, Maintenance, and Lifecycle Management

A true “total hose solution” extends beyond manufacturing. It includes technical consultation, on-site inspection, and replacement planning throughout the project lifecycle.Proper hose rotation, pressure monitoring, and periodic internal wear assessment can extend service life by 20–40%, according to operational data published by CEDA.

At YH Rubber Hose, we support our clients with detailed hose performance tracking, ensuring that maintenance schedules align with project cycles — minimizing downtime during critical dredging phases. For customers seeking quality products, we provide dredge hose for sale with guaranteed performance and durability.

Supporting Sustainable Dredging Operations

As the dredging industry moves toward sustainable and environmentally responsible operations, efficient pipeline systems play a vital role in reducing energy consumption and material waste. Optimized hose assemblies lower hydraulic resistance, which translates directly into lower fuel usage and carbon emissions from dredging vessels.

By integrating design expertise, material innovation, and lifecycle management, YH Rubber Hose provides a Total Hose Solution that helps dredging contractors achieve reliability, efficiency, and sustainability across every project stage.

References:

PIANC Technical Report No. 194 – Sustainable Dredging and Material Handling (2022)

CEDA’s Checklist for Successful Dredging Management

Field data and experience from YH Rubber Hose engineering projects

Recommended Reading:

- Dredging Hose Selection Questionnaire

- Understanding Materials, Length, and Applications for Optimal Dredging Performance

- Durable and Reliable Rubber Dredging Hose Solutions

- How Dredging Rubber Hoses Work with Different Types of Dredgers?

- Why Do Rubber Fenders Come in Different Colors?

- Marine Rubber Seals: Key Components for Ensuring the Safe Operation of Ships and Offshore Equipment

English

English