Marine fenders are essential components in maritime activities, designed to prevent damage to ships, docks, and berthing structures. They act as a crucial buffer, absorbing kinetic energy during vessel docking and berthing operations. With advancements in maritime engineering, especially from marine fender China manufacturers like Yonghong, marine fenders have evolved to meet diverse functional and environmental needs. This article explores the types, purposes, and benefits of marine fenders, alongside their construction materials, installation processes, and maintenance protocols. For those in the marine industry seeking dependable solutions, whether looking for dock fenders or large boat fenders, this guide provides valuable insights.

Marine Fender Definition and Types

Marine fenders are devices critical for safeguarding ships and docking facilities from potential damages caused by impact. They are categorized based on function, construction, and application environment, offering solutions that range from protecting small boats to fortifying major harbor installations. Here are some prevalent types of marine fenders:

| Type | Description | Application |

|---|---|---|

| Cylindrical Fenders | A versatile fender shape that offers reliable protection and installation flexibility. | Small vessels and docking piers. |

| Accordion Fenders | Specially designed for environments that require high energy absorption. | Major ports and industrial facilities. |

| Panel Fenders | Comprises a protective panel with an energy-absorbent core. | Ships that frequently experience heavy impact. |

| Arch Fenders | Known for their durability and resilience, ideal for contoured surfaces. | Harbor and quay structures. |

These types cater to different requirements, ensuring effective energy dispersion and protection across various maritime infrastructures.

Role in Boat Protection

The primary purpose of marine fenders lies in their ability to safeguard both vessels and berthing structures during maneuvers. By diffusing the energy generated when a vessel makes contact with a dock, fenders reduce the risk of damage to both the boat, with specific models for fenders for boats, and the dock. The following roles highlight their significance:

Energy Absorption: Fenders are designed to absorb and dissipate the kinetic energy of colliding boats, thereby minimizing structural impact.

Surface Protection: By creating a cushioning layer, they prevent direct contact and friction, reducing wear and tear on both the marine fender and vessel surfaces.

Enhanced Safety: Enhanced operational safety for crews and cargo handlers, preventing accidents due to collisions.

By strategically deploying marine boat fenders, operators can ensure safer and more efficient docking experiences. Additionally, the integration of ship sealing solutions further enhances protection against water ingress and structural damage.

Marine Fender Materials and Construction

The performance of marine fenders is largely influenced by the materials and construction techniques used. Various materials provide the specific properties needed for marine environments:

| Material | Properties |

|---|---|

| Rubber | Elasticity, toughness, exceptional rubber sealing |

| Foam Elastomer | High energy absorption, lightweight |

| Polyurethane | Durability, wear resistance |

| Composite Materials | Enhanced strength, resilience to extreme conditions |

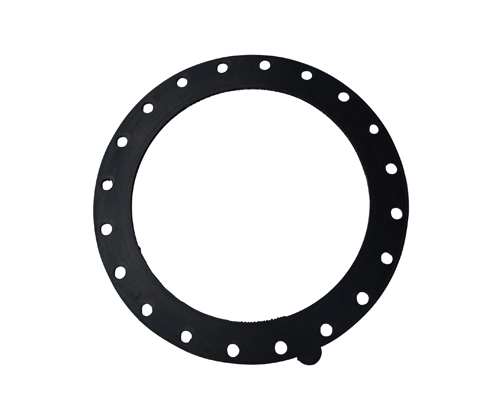

Materials like rubber gasket play a crucial role in the fender’s flexibility and ability to cope with diverse stress factors in marine environments. The combination of material selection and precise construction ensures fenders meet rigorous maritime demands. Leading sealing element suppliers often provide specialized components used in these fenders to guarantee optimal performance.

Marine Fender Installation Guidelines

Proper installation of marine fenders is essential for their optimal function. The steps involved in installation require precision and meticulous planning:

Site Assessment: Identifying specific docking requirements and environmental factors to select appropriate fender types and dimensions.

Mounting Considerations: Based on the fender type, select appropriate mounts using rubber pipe fittings or brackets ensuring stability and alignment, much like when installing a rubber hose connector.

Secure Fastening: Ensuring the fender is positioned correctly and securely to maximize its impact dampening capabilities.

Guidelines apply to both small and big boat fenders ensuring they provide effective protection and maintain structural integrity over time. Many dredge pipe suppliers also provide compatible fittings and hoses, such as self floating rubber hose, which integrate seamlessly with marine fender systems in dredging or sealing applications.

Common Maintenance Practices

To ensure marine fenders remain effective, regular maintenance is paramount. This includes:

Cleaning: Regular removal of salt, grime, and marine growth to prevent degradation of the materials.

Inspection: Routine checks for wear, tear, and potential cracks or damages that might compromise fender performance.

Repair and Replacement: Swiftly repairing minor damages or replacing heavily worn units with new fenders. This practice ensures continued operational efficiency.

Effective maintenance helps to maximize the longevity of fenders and minimize the risk of sudden failures, thus supporting continuous maritime activities. Products such as the mud suction hose are often part of the maintenance and dredging equipment lineup used alongside marine fenders to ensure operational success.

Conclusion

Understanding and employing the right rubber fender is critical for maritime safety and efficiency. Whether safeguarding a commercial dock or a personal yacht, choosing the appropriate fender type and ensuring proper maintenance are vital steps. By considering factors from materials like flexible rubber hose properties to precise installation, operators can protect their investments and enhance service reliability. Whether you require marine sealing solutions, dredge pipe integration, or maintenance dredging support for your maritime facility, a well-informed approach to marine fender selection and upkeep can significantly bolster operational outcomes.

Don't Miss These Blogs

floating dredging hose market analysis report

- Maximize Your Dredging Efficiency with Premium Rubber Suction Hoses

- The Advantages of Zhenjiang Dredging Rubber Hose

- Situation and Development of the Dredge Rubber Hose

- Understanding Materials, Length, and Applications for Optimal Dredging Performance

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Total Hose Solution for Dredging Projects

English

English