Bending performance is one of the most critical safety and reliability parameters for self‑floating dredging hoses. In real operation, a floating line is never perfectly straight: waves, currents, tidal variations and vessel movements continuously force the hose to work in a curved shape. If the hose cannot safely accommodate this cyclic bending under pressure, problems such as local kinking, partial collapse of the bore, layer delamination or cracking of the buoyancy layer may occur. These defects not only shorten service life but can also lead to sudden failure, unplanned

downtime and serious environmental or economic losses.

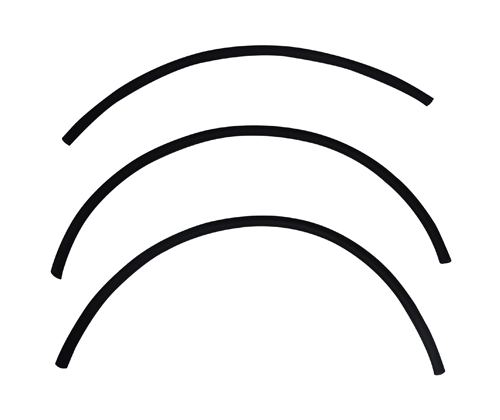

For this reason, a bending test is not just a “nice‑to‑have” demonstration; it is effectively a necessary performance verification whenever an allowable bending angle is promised to the customer. By pressurizing the hose to working pressure and bending it step by step from 0° up to the specified angle (for example 45°), the test confirms that the hose maintains a smooth inner bore, no leakage, no visible damage to the buoyancy layer and no abnormal deformation throughout the full bending range. This provides objective evidence that the actual bending capability matches the design and the datasheet.

In professional dredging projects, owners, contractors and inspection bodies increasingly expect this kind of full‑scale bending test as part of type approval or pre‑shipment inspection. Carrying out and documenting the bending test therefore helps ensure safety in real sea states, supports compliance with modern industry practice and gives end users confidence that each floating hose will perform reliably throughout its service life.

Here is a clear, “standard‑style” procedure for this test

1. Preparation and visual check

- Lay the self‑floating dredging hose straight on level ground, with enough free length for bending.

- Inspect outer cover, flanges and buoyancy layer for visible damage, cuts or deformation.

2. Instrumentation and set‑up

- Connect the hose to a test manifold with suitable blind flanges and pressure gauge.

- Mark reference points along the hose to help measure bending angle or radius.

- If needed, prepare a simple template or frame to control the target bend (for example, 0–45°).

3. Pressurization to working pressure

- Fill the hose with water (or another safe test medium) and remove air as far as practical.

- Increase internal pressure gradually up to the specified working pressure (or test pressure agreed with the customer).

- Hold the pressure stable during the bending operation.

4. Bending under pressure

- With the hose at pressure, slowly bend the test section from straight (0°) to the specified maximum test angle (for example 45°), or to the specified minimum bend radius.

- Keep the bend for a defined time (e.g. several minutes) to simulate working conditions.

- During bending, check that:

- the inner bore remains smooth (no kinking, no local collapse),

- the curvature is even (no sharp “dog‑leg” points),

- the floating body does not crack, detach or wrinkle abnormally,

- no leakage appears at body or end connections.

5. Return and re‑inspection

- Slowly return the hose from the bent position to straight while still under pressure.

- Depressurize and drain the hose safely.

- Re‑inspect for any permanent deformation, damage to cover or float, or movement of the end fittings.

6. Acceptance criteria (typical)

- No visible leakage.

- No kinking or local collapse at or below the specified test angle.

- No visible damage or separation of the buoyancy layer.

- End fittings remain tight, with no measurable pull‑out or rotation.

Partner with YongHong in Self-Floating Dredging Hose Solutions

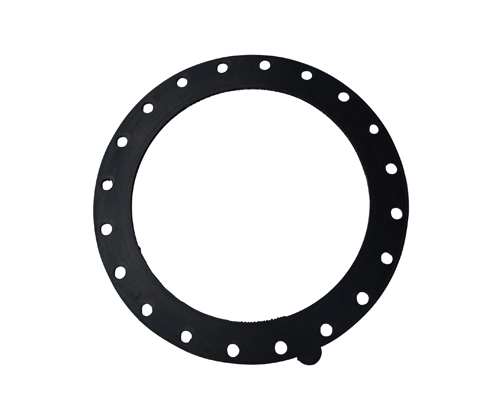

For YH Rubber, before our shipment, each self‑floating dredging hose is subjected to a bending test under working pressure. The hose is bent from 0° up to 45° in simulated operating conditions to confirm there is no kinking, no leakage and no abnormal deformation, ensuring safe performance and consistent quality in service. Combined with wear-resistant compound formulations and our global manufacturing excellence, partnering with YongHong, one of the leading dredge pipe suppliers, gives you self-floating hose solutions that improve operational stability, reduce downtime, and support successful project execution in challenging marine applications.

FAQs

Q1: What is a floating hose?

A floating hose is a type of flexible pipeline used to transfer fluids (such as slurry, crude oil, or water) in marine or dredging operations. It is designed with buoyant materials to float on the water's surface, enabling easy handling and alignment.

Q2: How does a self-floating dredge hose save on maintenance compared to rigid pipelines?

Integrated buoyancy and flexible structure reduce the need for extra floats or supports, simplifying installation and minimizing routine maintenance costs.

Q3: Can self-floating dredge hoses be customized for specific project needs?

Yes, they can be ordered in different diameters, lengths and pressure ratings, and with selected end fittings to match unique dredging requirements.

Q4: What applications beyond dredging can a self-floating dredge hose be used for?

Beyond conventional dredging, they’re used in environmental remediation, beach nourishment and offshore slurry transfer where buoyant, flexible conduits are needed.

- Marine Fender Suppliers: The Invisible Guardians of Port Safety

- Dredging Rubber Hoses in Belt and Road Infrastructure Projects

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Structural Design and Application Advantages of Armored Hose

- Case Study: Small Dredging Project at a Local Marina

- Introduction of Floating Rubber Hose

English

English