In today's globally busy maritime shipping, ports and docks have become crucial hubs connecting world trade. Every day, thousands of ships dock, load, unload, and set sail. In this process, a critical yet often overlooked component plays a vital role—the marine fender. The specialized manufacturers providing products, technology, and services for these fenders, known as marine fender suppliers, are the invisible guardians ensuring port safety and ship operation efficiency.

What is a Marine Fender?

A marine fender is a type of cushioning device installed on the dock or the edge of the ship's hull. It is used to absorb impact energy when ships dock, preventing direct collision between the hull and port structures, thereby protecting both from damage. It can absorb a large amount of energy while maintaining a small reaction force, making it an indispensable protective facility in modern ports.

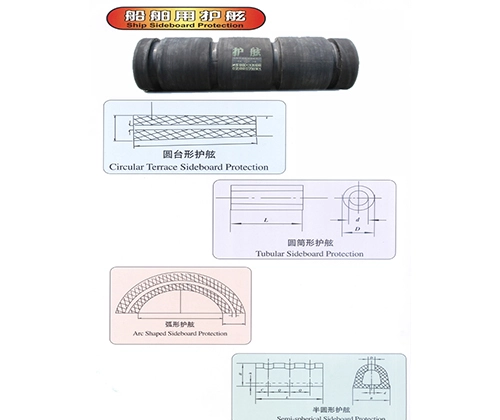

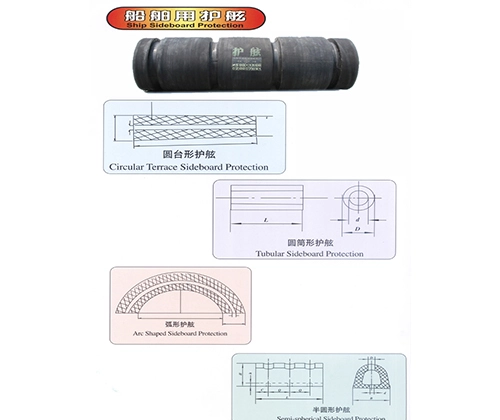

Common materials for fenders include rubber, foam, composite materials, etc. They can be categorized by shape into cylindrical, cone-shaped, D-shaped, arch-shaped, rectangular, and other forms to meet the needs of different types of docks and ships.

Main Application Scenarios of Marine Fenders

Marine fenders are widely used in the following scenarios:

Commercial port docks: container terminals, bulk cargo docks, oil and gas berths, etc..

Offshore platforms and floating berths: used to cushion collisions between platforms and operational vessels.

Military ports and special docks: need to meet high strength impact resistance requirements.

Shipyards and dry docks: used for temporary docking of new and repaired ships.

Inland ports and tourist piers: mainly D-type and small fenders, suitable for use by small ships.

The Role of Marine Fender Suppliers

A qualified fender supplier is not just a manufacturer of products but also a provider of safety solutions for ports and ships.

Product Customization and Design

Different docks have different berthing angles, water depths, tidal differences, and berth types. Fender suppliers provide customized designs based on customer needs to ensure the fender's energy absorption performance, size, and weather resistance meet actual application conditions.

Material and Quality Control

Excellent suppliers strictly control the source of raw materials, using high-quality rubber, steel, or composite materials to ensure that the fenders have good impact resistance, aging resistance, and corrosion resistance, meeting the long-term use requirements of ports.

Technical Support and Installation Guidance

From scheme design to on-site installation, suppliers usually have a technical team to provide full-process support, ensuring the correct installation and reasonable distribution of fenders, maximizing their effectiveness.

Post-maintenance and Replacement Suggestions

Although fenders are passive devices, they also have aging and wear cycles. Suppliers will provide regular maintenance and replacement services based on product lifespan, reducing safety hazards.

Conclusion

Though marine fenders may be considered a "small role" in port infrastructure, their function cannot be ignored. As one of the professional marine fender suppliers, Yonghong can provide high-quality products. Whether for large international ports or small to medium-sized docks, choosing Yonghong is the most basic and necessary guarantee for maritime safety.

Other Dredging Hoses and Sealing Elements You May Also Like

- Installation Process of Marine Rubber Fender

- What You Need to Know Before Selecting Floating Hoses for Dredging Projects?

- What Is the Difference Between Armored Hoses and Common Rubber Hoses?

- Regional Differences Impact on Dredging Rubber Hose Selection

- Power 2+ Years of Zero Downtime in River Maintenance

- Understanding the Regional Distribution of Dredging Rubber Hose in China

English

English