Under the impetus of the Belt and Road Initiative, overseas infrastructure construction has witnessed a surge of vigorous development. In major projects such as ports, waterways, and artificial islands, dredging operations are an indispensable critical component. As the “lifeline” connecting dredgers to sediment disposal areas, the application and development of dredging rubber hoses have provided crucial support for the smooth implementation of these projects.

Dredging rubber hoses are primarily used to transport mixtures of silt, gravel, coral reefs, and other materials. Their high abrasion resistance, high toughness, and wave-resistant properties enable them to play a crucial role in the harsh marine construction environment. In numerous large-scale infrastructure projects along the Belt and Road Initiative, Chinese-made dredging rubber hoses can be seen working alongside advanced dredging equipment to ensure the success of these projects.

Core Application Areas

Under the Belt and Road Initiative framework, dredging rubber hoses are primarily applied in the following core infrastructure sectors:

Port Construction and Channel Dredging: Many countries along the Belt and Road Initiative have advantageous geographical locations but lagging port facilities and severely silted channels. By utilizing large dredgers and dredging rubber hoses, efficient port basin excavation, channel dredging, and terminal expansion can be achieved. For example, in projects such as the Gwadar Port in Pakistan and the Colombo Port City in Sri Lanka, large-scale dredging operations have laid a solid foundation for port modernization and increased cargo handling capacity. These projects typically require the transportation of tens of millions, or even hundreds of millions, of cubic meters of sediment to designated areas, placing extremely high demands on the durability and connection stability of rubber hoses.

Port-adjacent industrial zones and new city development: Many Belt and Road Initiative projects are not limited to port construction but also include the development of port-adjacent industrial zones and new cities. These projects often require land reclamation through dredging and filling to acquire valuable land resources. Dredging rubber pipelines play a crucial role in continuously transporting excavated seabed sand and silt to designated areas during this process. The expansion of Kuantan Port in Malaysia and the development of its surrounding industrial zones are prime examples of such projects.

Artificial Island Construction and Tourism Development: In some coastal countries rich in tourism resources, the construction of artificial islands using land reclamation technology to develop high-end tourism has become a highlight of Belt and Road cooperation. In these projects, the application of self-floating dredging rubber hoses is particularly widespread. These hoses can float on the sea surface, rising and falling with the waves, forming flexible mud discharge pipelines, significantly improving construction efficiency and adaptability to complex sea conditions.

Technological Highlights and the Strength of Chinese Manufacturing

As China's dredging technology continues to advance, the performance of domestically produced dredging rubber hoses has reached world-leading levels. Take the “Tiankun” self-propelled cutter suction dredger, hailed as the “island-building marvel,” as an example. Its efficient operations in overseas Belt and Road Initiative projects are closely tied to the advanced dredging pipelines it employs.

Chinese dredge rubber hose manufacturers are now capable of producing large-diameter, high-pressure, ultra-wear-resistant dredging rubber hoses. These products from brands like Yonghong feature the following characteristics:

High strength and wear resistance: Capable of withstanding continuous erosion from high-velocity flows containing sand, gravel, coral reefs, and other hard materials.

Excellent flexibility and resistance to bending: They can adapt to the movement and turning of dredgers during operations and withstand the impact of rough sea conditions.

Reliable connectivity: Equipped with sturdy and reliable flange connections to ensure no leaks occur during prolonged, high-intensity operations.

Self-floating capability: Many dredging pipelines adopt a self-floating design, where buoyancy materials are wrapped around the outer layer of the pipeline, enabling it to float on the water surface for easy installation and movement.

Challenges and Outlook

Although dredging rubber hoses have played a significant role in Belt and Road Initiative projects, their application also faces certain challenges. For example, in some project host countries, environmental regulations are becoming increasingly stringent, imposing higher requirements on the environmental impacts of dredging operations. This is driving the development of dredging technology and related equipment, including rubber hoses, toward more environmentally friendly and efficient directions.

Looking ahead, as the Belt and Road Initiative continues to deepen, the demand for infrastructure such as ports and waterways along the route will continue to grow. This will open up broader market opportunities for China's dredging industry and dredging rubber hose manufacturing sector. At the same time, requirements for product performance, environmental standards, and intelligentization levels will continue to rise, driving Chinese enterprises to play a more significant role in the global infrastructure market.

Other Dredging Hoses and Sealing Elements You May Also Like

- Self-Floating Dredge Hose: A Competent Assistant in Hydraulic Engineering

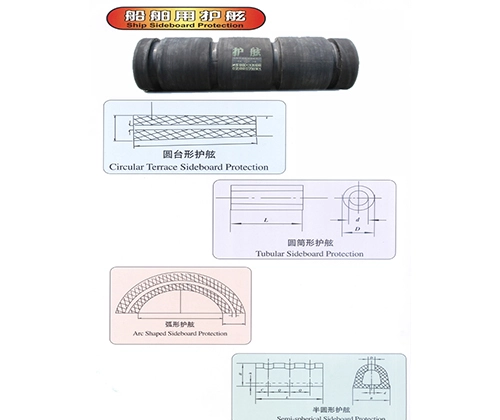

- Rubber Fender For Ship: A New Type of Fender Equipment

- Total Hose Solution for Dredging Projects

- Mastering Dredging with High-Performance Hoses

- Situation and Development of the Dredge Rubber Hose

- Selection Suggestions for Rubber Dredging Hoses

English

English