In dredging and slurry transport systems, rubber hoses are critical components that connect pumps, pipelines, and dredging equipment. However, not all rubber hoses are designed for the same operating conditions. Two commonly used types are armored hoses and common (non-armored) rubber hoses.

Understanding the differences between them helps project owners and contractors choose the right hose for their application — balancing durability, cost, and operational safety.

Basic Definition

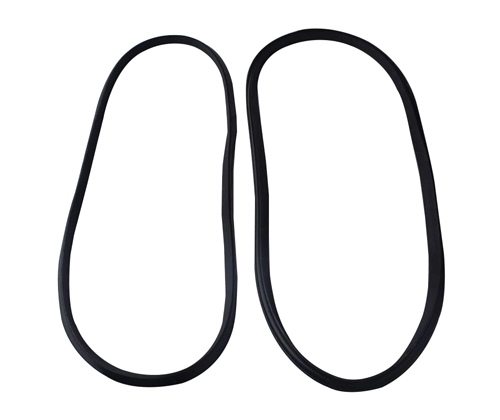

Common Rubber Hoses

Common rubber hoses are constructed with:

· An inner wear-resistant rubber lining

· Reinforcement layers (textile or steel cord)

· An outer rubber cover

They are designed primarily to handle internal pressure and abrasion from slurry under normal operating conditions.

Armored Rubber Hoses

Armored hoses have the same internal structure as common rubber hoses but add:

· An external protective layer, usually steel rings, chains, or metal armor

This armor protects the hose from external mechanical damage, not internal pressure.

Key Differences at a Glance

Aspect | Common Rubber Hose | Armored Rubber Hose |

Internal wear resistance | High | High |

External impact protection | Limited | Very high |

Resistance to dragging / abrasion | Moderate | Excellent |

Weight | Lighter | Heavier |

Flexibility | Higher | Slightly reduced |

Cost | Lower | Higher |

Typical service life in harsh environments | Shorter | Longer |

Where Common Rubber Hoses Are Typically Used

Common rubber hoses are suitable when:

· The hose is well supported or suspended

· External contact with rocks or structures is minimal

· The operating environment is relatively controlled

Typical applications include:

· Floating pipeline sections

· Pump discharge connections

· Dredger-to-steel pipe transitions

· Booster station connections

In these cases, the main challenge is internal abrasion, not external impact.

Where Armored Hoses Are Necessary

Armored hoses are used when hoses face constant external stress, such as:

· Dragging on riverbeds or seabeds

· Contact with rocks, coral, or debris

· Exposure to sharp edges or construction structures

· Shallow-water or near-shore dredging

· Amphibious dredger operations

The external armor acts as a physical shield, preventing cuts, crushing, and excessive wear on the rubber cover.

Durability vs. Flexibility Trade-Off

Armored hoses:

· Last significantly longer in harsh environments

· Reduce failure risk in high-impact zones

However:

· They are heavier

· Less flexible than standard hoses

· Require stronger handling equipment

Because of this, armored hose is usually installed only in high-risk sections, while common hoses are used elsewhere in the pipeline system.

Cost Considerations

Armored hoses typically cost more due to:

· Additional materials (steel rings or chains)

· More complex manufacturing

· Higher transportation weight

However, in environments with severe external abrasion, the total cost of ownership is often lower, as armored tube reduce:

· Replacement frequency

· Downtime

· Emergency repair costs

How to Choose Between Armored and Common Hoses

A practical selection approach:

· Use common rubber hoses for floating lines and protected areas

· Use armored hoses in zones with seabed contact or high impact risk

· Combine both into a Total Hose Solution for optimal cost and performance

Conclusion

The key difference between armored hoses and common rubber hoses lies in external protection.

Both can handle slurry pressure and internal abrasion, but armored hoses are designed to survive harsh physical environments where standard hoses would fail prematurely.

Choosing the right type — or the right combination — is essential for safe, efficient, and cost-effective dredging operations.

Need Help Selecting the Right Hose Type?

As one of the professional dredge pipe suppliers, we manufacture:

· Common dredging rubber hoses

· Armored dredging hoses

· Floating and suction hoses

· Customized hose assemblies for different dredger types

If you need technical advice or project-specific recommendations, feel free to contact us for support.

FAQs

Q1: What is a marine hose?

Marine hoses are important for transporting fluids like fuel, water and waste. Each type of marine hose has a specific purpose, ensuring your boat functions well and reducing the risk of leaks, spills and accidents.

Q2: What are the different types of marine hoses?

What types of marine hoses are used on boats? Marine hoses include wet exhaust hoses, fuel hoses, bilge pump hoses, sanitation hoses, ventilation/blower hoses, potable water hoses, and garden hoses, each designed for a specific application on the boat.

Q3: Why might a marine armored hose tube include a tensile armor layer?

A tensile armor layer made of steel wire or metal enhances the hose’s tensile strength, preventing damage from external tension and bending during vessel movement.

Q4: Can marine armored hose tubes be customized for specific dredging conditions?

Yes, marine armored hose tubes can be customized in diameter, length and reinforcement features to suit unique project requirements such as abrasive materials and pressure range.

- Optimizing Sand Dredging in Australia: The Role of Custom Rubber Dredge Hoses

- Mastering Dredging with High-Performance Hoses

- Marine Fender Suppliers: The Invisible Guardians of Port Safety

- The Advantages of Zhenjiang Dredging Rubber Hose

- Unleash the Power of Your Projects with Advanced Sand Suction and Discharge Rubber Hoses

- Dredging Hoses in Hydraulic and Mechanical Operations

English

English