In current dredging practice, there is almost no need for a “self‑floating suction hose”, so it has not evolved into a standard product category.

Where the suction hose actually works?

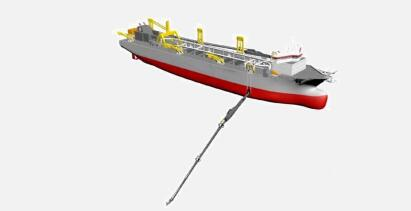

On both cutter suction dredgers (CSD) and trailing suction hopper dredgers (TSHD), the suction line usually works below or close to the hull, not as a long floating line on the water surface.

- On a TSHD, the mud suction hose segments are mounted on the drag arm between the ship and the draghead, working mostly submerged and supported by the steel structure of the arm.

- On a CSD, the mud suction hose is arranged between the cutter ladder and the pump on board, again supported by steel pipes, ladders or frames, not as a free‑floating surface pipeline.

In other words, suction hoses work in zones where buoyancy is provided by the steel structure and the vessel, not by the hose itself. There is no engineering need for them to “float” as an independent surface line.

Why discharge hoses need self-floating, but suction hoses don’t?

Self‑floating design is introduced to solve specific problems of long surface discharge pipelines.

- Keeping a long line at a stable freeboard on waves

- Reducing bending stress and kinking when the sea state changes

- Avoiding sinking of the line between pontoons

- Withstanding axial tension during towing or repositioning

These problems appear on discharge pipelines laid on the water surface, not on the short, structurally supported suction segments near the vessel. That is why self-floating dredge hose in catalogues is specified as self‑floating discharge hoses, designed for surface lines from ship to shore or between floating sections.

For suction segments:is

- Length is relatively short.

- Layout is dictated by the drag arm or ladder geometry.

- Weight and balance are handled by the steel arm, winches, and sometimes steel floats, not by hose foam.

Adding a thick buoyancy layer to suction hoses brings extra diameter, stiffness and cost, but does not solve a real engineering problem in that location.

Suction lines work close to the vessel and under high vacuum plus pulsating loads. Dredging companies generally prefer robust, easily inspected and well‑supported hose/pipe assembliesat this critical position.

- If a self‑floating suction hose were damaged, trapped air or water in the buoyancy layer could complicate inspection and repair.

- Any change in buoyancy along a structurally supported arm segment might interfere with the arm’s balance and control.

For discharge lines, by contrast, self‑floating hoses are easier to monitor visually on the water surface, and the main design challenge is staying afloat and flexible, not integration with a steel arm.

How manufacturers classify products instead

Because of the above practical and structural reasons, manufacturers and dredging contractors have converged on a de facto standard taxonomy:

- By function:

- Suction dredge hose (non‑floating)

- Discharge dredge hose (non‑floating)

- By form:

- Self‑floating discharge hose (for surface lines)

- Non‑floating hose (for onboard / submerged sections)

- By reinforcement:

- Standard, armoured, ceramic‑lined, etc.

In this system, "self‑floating" is treated as a form option for discharge hoses, not as a general attribute that can be applied meaningfully to suction hoses. Hence, catalogues and standards talk about “self‑floating dredging hoses” or “self‑floating discharge hoses”, but do not define a standard category called “self‑floating suction hose.

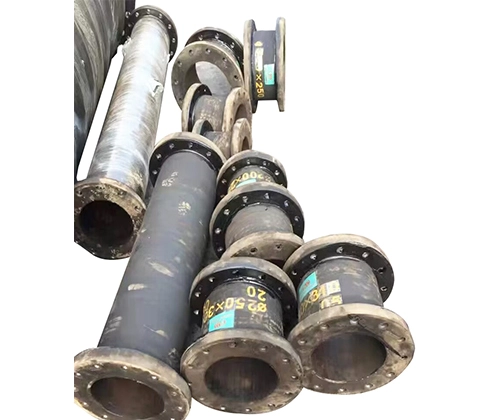

Partner with YongHong in Suction Hose Solutions

At YongHong, we view suction hoses as more than a standard pipeline component—they are a critical interface where material science, structural design, and real-world dredging conditions converge. By combining abrasion-resistant rubber compounds with optimized reinforcement for vacuum stability, we engineer suction hoses that perform reliably under heavy slurry loads, dynamic bending, and harsh marine environments. Our manufacturing expertise allows us to balance flexibility, strength, and service life, ensuring stable performance from dredger intake to pump connection. Through close collaboration with project owners and contractors, YongHong delivers suction rubber hose solutions that reduce operational risk, extend service intervals, and support long-term efficiency in demanding dredging operations.

FAQs

Q1: What is a self‑floating dredging hose?

A: A self‑floating dredging hose is a rubber hose with an integrated buoyancy layer so that the hose itself can float on the water surface without separate pontoons, mainly used in surface discharge pipelines for transporting slurry from ship to shore or between floating sections.

Q2: Why is there no standard “self‑floating suction hose”?

A: In real dredging layouts, suction hoses work close to the vessel on the drag arm or cutter ladder and are structurally supported by steel pipes and frames, so they do not need built‑in buoyancy. Self‑floating designs mainly solve problems of long floating discharge lines, not short, supported suction segments.

Q3: Can a suction hose be made self‑floating if a project requires it?

A: In theory, a mud suction hose could be designed with additional buoyancy, but in practice this is rarely necessary and may even create issues in arm balance, space, bending stiffness and maintenance. For this reason, it is not offered as a standard product and would only be considered as a very specific custom solution.

Q4: What are the typical applications of self‑floating hoses?

A: Self‑floating hoses are typically used on surface discharge pipelines, including ship‑to‑shore lines, floating lines in sheltered waters, and sections that must follow wave motion while maintaining a safe freeboard, flexibility and resistance to axial tension during towing or repositioning.

Q5: How are suction hoses classified if they are not self‑floating?

A: Suction hoses are usually classified by function (suction), reinforcement (standard, armored, etc.) and connection type, and are designed to withstand high vacuum and repeated bending on the drag arm or ladder. They are normally non‑floating components integrated into the steel structure rather than independent floating elements.

[Reference]

[1](https://jerryborgmarine.com/blog/what-is-a-dredging-hose/)

[2](https://www.zavamarine.com/definition-and-selection-of-marine-dredge-hose/)

[3](https://www.floatinghosesllc.com/product/dredging-armored-floating-hoses)

[4](https://www.sincopipe.com/resources/what-should-you-consider-when-selecting-a-dredge-hose-101.html)

[5](https://www.cdsr-tech.com/armored-hoses-product/)

English

English