With the advancement of science and technology, dredging technology has evolved rapidly, and we now have a variety of advanced dredging equipment. New and advanced dredging equipment continues to emerge, adapting to soil quality and site conditions, significantly improving construction efficiency.

Two Mainstream Dredging Methods

Hydraulic dredging machinery

Hydraulic dredging machinery is a common piece of equipment in major river dredging companies.

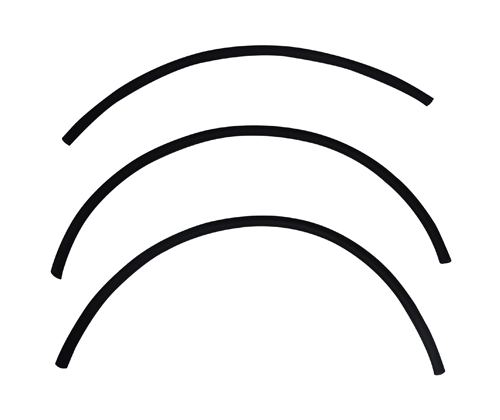

It is important to note that water inflow into the construction area, especially the construction zone, must be blocked before dredging operations can begin. Typically, a 22-kilowatt vertical mud pump and a 15-kilowatt high-pressure clean water pump are used. Additionally, the dredging unit requires a mud pump and approximately 150-millimeter rubber mud hoses. A suitable power transformer is connected to the local power supply to establish the dredging construction power distribution system. If the construction site is remote and lacks grid power, a diesel generator set is required for power supply. The dredging capacity of this hydraulic dredging unit is approximately 400–500 m³/day, with the number of machines influenced by the total dredging volume and construction duration.

Dredging Operations of Dredgers

Dredgers typically refer to cutter suction dredgers, which have the advantage of being able to operate sequentially from one side of the river to the other. After positioning the dredger, the cutter head is placed on the riverbed to cut and crush the sediment, turning it into slurry. When a cutter suction dredger with a capacity of 80–120 m³/h is in operation, the dredging distance must be controlled within 1 km. The mud pipe should use Φ300 mm steel pipes. The underwater section of the dredging pipe uses underwater pipes or floating pipes. When encountering a bent bank slope, rubber hoses must be connected, and sandbag frames are extended from the shore to the accumulation area. Open spaces such as fish ponds or farmland are typically used as disposal areas. To prevent leakage, clay embankments and filled edges are commonly employed.

Comparison of the two dredging methods

The hydraulic dredging machine method is particularly suitable for rivers and can be used to cut off rivers, as the dredging depth is shallow, and the soil is typically composed of silt with high water content. Accordingly, it is not suitable for dredging navigable waterways. If the target river requires deep dredging, excavation of highly permeable soil layers, or if there are flood walls along the banks, the machine should be used with caution. The primary advantage of this method lies in its simple structure, ease of construction, and mobility, with various components capable of flexible relocation, and construction quality being easily controlled. However, due to the need for a large number of units to operate simultaneously, compared to dredging vessel operations, hydraulic dredging machine construction requires clear weather conditions, the construction river must not be a navigable waterway, and drainage operations are necessary during construction.

Dredgers, compared to excavator units, can be used in non-navigable or navigable waterways, compensating for the shortcomings of excavator units. However, they require nearby soil filling, with a mud disposal distance not exceeding 1 km. The advantages of dredger dredging operations include the ability to construct underwater without affecting the existing river's drainage and without impacting existing roads. Compared to excavator units, they can also operate under non-extreme weather conditions, even during the rainy season, as long as it is within safe limits. Conversely, the disadvantages of dredging operations using dredgers include the need to operate close to the pile, with the produced slurry having a lower clay content and higher water content, resulting in a large volume of tailwater. The drainage work for accumulated soil is labor-intensive, which can significantly impact the existing environment, and quality control during underwater construction is challenging.

- Power 2+ Years of Zero Downtime in River Maintenance

- Selection Suggestions for Rubber Dredging Hoses

- Self-Floating Dredge Hose: A Competent Assistant in Hydraulic Engineering

- Types of Dredging Hoses Suitable for Capital Dredging Works

- Understanding the Regional Distribution of Dredging Rubber Hose in China

- Sewer Seal Ring: Securing Urban Infrastructure

English

English