Dredging rubber hoses are critical components in water conservancy and dredging projects worldwide, enabling the efficient transport of sediment and water under demanding conditions. In 2024, China's dredging industry handled approximately 1.2 billion cubic meters of sediment, with rubber hoses accounting for 15-20% of equipment costs, according to the China Dredging Association. Based on insights gathered from interviews at the Yangtze River dredging site in Nanjing, this article outlines the structure, usage guidelines, and maintenance practices for these hoses, often referred to as "rubber bands" by engineers due to their flexibility and strength.

The design of a dredging rubber hose resembles a "sandwich," with each layer serving a specific function to ensure durability and performance:

Liner Layer: Composed of 5 mm thick wear-resistant rubber (typically a blend of natural and nitrile rubber), this layer withstands abrasive sediment. Its surface features fine, sandpaper-like textures to enhance resistance to wear.

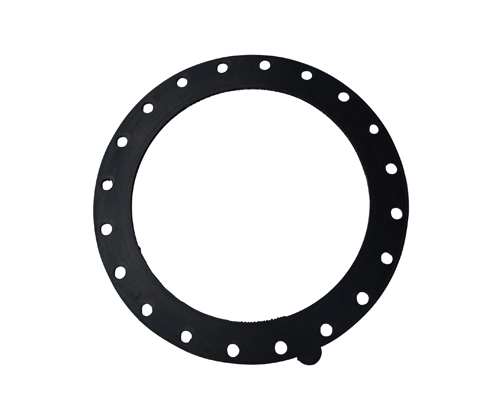

Reinforcement Layer: A cross-wrapped steel wire mesh provides structural integrity, acting as a "bulletproof vest" to resist internal pressure up to 10-15 bar.

Outer Layer: Made of rubber infused with UV-resistant additives, this layer protects against environmental degradation and exhibits a faint blue sheen under sunlight.

The following table summarizes the hose's layered structure:

Layer | Material | Thickness | Function |

Liner Layer | Wear-resistant rubber | 5 mm | Resists abrasion from sediment |

Reinforce- ment Layer | Steel wire mesh | 2-3 mm | Provides structural strength |

Outer Layer | UV-resistant rubber | 3 mm | Protects against UV and environmental wear |

Usage Guidelines: The "Five Taboos"

Proper handling of dredging rubber hoses is critical to maximizing their lifespan, typically 2-3 construction seasons (18-24 months). Based on field practices, the following guidelines, known as the "five taboos," are essential:

1. Avoid Prolonged Sun Exposure: Direct sunlight accelerates rubber aging, reducing elasticity. Use UV-protective covers or store hoses in shaded areas.

2. Avoid Excessive Bending: The bending radius must be at least six times the hose diameter (e.g., 4.8 m for an 800 mm hose) to prevent permanent deformation of the steel wire layer.

3. Avoid Dry Operation: Before starting the pump, fill the hose with water to lubricate the liner. Idling for as little as 5 minutes can cause significant wear to the inner layer.

4. Avoid Mismatched Connections: Flange sizes may vary by 2-3 mm between manufacturers, leading to leaks if mismatched. Always verify compatibility before installation.

5. Avoid Overpressure: Operating beyond the recommended pressure (indicated by the red zone on pressure gauges, typically above 15 bar) risks hose rupture. Stop operations immediately if overpressure occurs.

Maintenance and Repair Practices

Effective maintenance extends the service life of dredging hoses and reduces downtime. Workers at the Nanjing site shared the following field-tested techniques:

Leak Management: Use specialized pipe clamps (available in three sizes for different hose sections) to address leaks at connection points or damaged areas.

Master Wang, a welder with 15 years of experience, emphasized the importance of customized tools: "Our team uses self-made clamps tailored to the hose’s diameter and leak location, saving hours of downtime."

Dredging rubber hoses are vital to the success of dredging projects, from maintaining navigable waterways to supporting global infrastructure development. By understanding their structure, adhering to usage guidelines, and implementing effective maintenance, operators can optimize performance and reduce costs. As technology advances, these "rubber bands" will continue to evolve, playing an even greater role in sustainable and efficient dredging operations.

- Smart Hose Systems for Amphibious Dredgers

- Durable and Reliable Rubber Dredging Hose Solutions

- What Is the Difference Between Armored Hoses and Common Rubber Hoses?

- What You Need to Know Before Selecting Floating Hoses for Dredging Projects?

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- Marine Fender Suppliers: The Invisible Guardians of Port Safety

English

English