In dredging projects, the dredger often receives the most attention. However, the efficiency, continuity, and safety of dredging operations depend just as heavily on another critical component: the dredging rubber hose system.

Different types of dredgers impose very different operational demands on hoses. Understanding this relationship helps project owners, contractors, and procurement teams select hose designs that truly match their dredging equipment — not just in size, but in function, durability, and reliability.

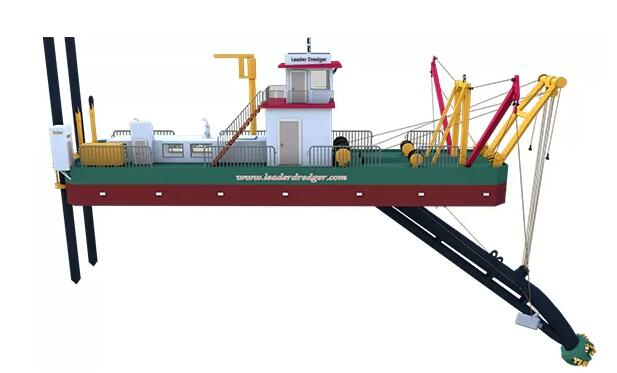

Cutter Suction Dredgers (CSD): High Pressure, High Abrasion

Cutter suction dredgers are widely used for port construction, river deepening, and land reclamation. They operate by cutting compacted seabed material and pumping slurry through pipelines over long distances.

Hose requirements for CSDs:

· High-pressure resistance to withstand continuous pumping

· Thick, wear-resistant inner lining for sand, gravel, and compacted soil

· Strong reinforcement layers to prevent deformation

· Accurate flange alignment for connection with pumps and steel pipelines

In CSD operations, dredging rubber hoses typically serve as:

· Flexible connections between the dredger and steel pipelines

· Shock absorbers near pump outlets

· Transition elements between floating rubber hose and rigid lines

A hose failure in a CSD system often leads to full system shutdown, making durability and pressure stability critical.

Trailing Suction Hopper Dredgers (TSHD): Flexibility and Fatigue Resistance

TSHDs collect sediment through drag arms while sailing and discharge material either through bottom doors or via pumping systems.

Hose requirements for TSHDs:

· Excellent flexibility to accommodate vessel movement

· High fatigue resistance for repeated bending

· Strong abrasion resistance for slurry discharge

· Stable dimensional accuracy for deck-mounted systems

Rubber dredge hoses in TSHD operations are commonly used for:

· Shore discharge pipelines

· Pump-to-pipe transitions

· Floating discharge systems

Unlike CSDs, TSHD hoses experience frequent motion and dynamic stress, making fatigue life more important than static pressure rating alone.

Amphibious Dredgers: Compact Design, High Wear Exposure

Amphibious dredgers operate in shallow water, wetlands, and environmentally sensitive areas. Their compact size and mobility create unique challenges for hose systems.

Hose requirements for amphibious dredgers:

· High abrasion resistance due to shallow-water sediment

· Compact bending radius for limited space

· Lightweight construction without sacrificing strength

· Reliable outer cover protection against debris and shoreline contact

In these systems, hoses are often exposed to direct mechanical contact, making outer-layer durability as important as internal wear resistance.

Bucket Ladder Dredgers: Continuous Mechanical Stress

Bucket ladder dredgers excavate material using a continuous chain of buckets, typically handling coarse and abrasive material.

Hose requirements for bucket dredgers:

· Heavy-duty construction

· Strong impact resistance

· High structural stability

· Secure flange connections

Here, hoses are often used downstream of mechanical discharge points and must withstand irregular slurry flow and impact forces.

Jet Suction Dredgers and Small Portable Units: Simplicity and Reliability

Used for sand mining and small-scale dredging, these systems prioritize ease of installation and operational flexibility.

Hose requirements:

· Moderate pressure resistance

· Good flexibility

· Cost-effective durability

· Easy replacement and maintenance

While less demanding than large marine dredgers, consistent quality remains essential to avoid frequent downtime.

Why Matching Hose Design to Dredger Type Matters

Selecting hoses without considering dredger type often leads to:

· Premature wear

· Unexpected downtime

· Increased maintenance cost

· Safety risks

Professional dredging projects therefore approach hose selection as a system-level decision, not a standalone product purchase.

Total Hose Solution: A System Perspective

Modern dredging projects increasingly adopt a Total Hose Solution approach — selecting different hose types, structures, and specifications based on:

· Dredger type

· Pump pressure

· Slurry characteristics

· Installation layout

· Environmental exposure

This approach reduces failure risk and improves long-term operational stability.

Need Help Matching Hoses to Your Dredger?

As one of the dedicated dredge pipe suppliers, we provide:

· Technical guidance based on dredger type

· Customized dredging hose assemblies

· Engineering drawings and test reports

· Export-ready marine-grade solutions

If you’re planning a new dredging project or upgrading existing equipment, we’re ready to support you with a reliable hose solution.

FAQS

Q1: How does a dredge rubber hose help reduce equipment vibration?

Flexible dredging hoses absorb pump and vessel movement vibrations, reducing stress on rigid pipelines and lowering the risk of mechanical fatigue and leaks.

Q2: What is a dredge pipe used for?

Dredge pipe refers to steel pipe specifically used in dredging operations where a combination of water and solids (typically silt, sand, gravel, or debris) is pumped through the pipe to remove or transport sediment.

Q3: How can proper maintenance extend the life of the dredge rubber hose?

Regular inspection, cleaning after use, avoiding sharp bends and storing dredging rubber hoses properly reduces abrasion, prevents internal damage and significantly extends service life.

Q4: Are dredge rubber hoses interchangeable between different dredger models?

They can be adapted, but proper diameter, flange type and pressure rating must be matched to each dredger’s specifications for safe and efficient performance.

- Why Suction Hoses Aren’t Designed as Self‑Floating?

- Marine Rubber Seals: Key Components for Ensuring the Safe Operation of Ships and Offshore Equipment

- Maximize Your Dredging Efficiency with Premium Rubber Suction Hoses

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- Hydraulic vs Mechanical Dredging

- Application of Dredging Rubber Self-Floating Hose in Port Maintenance

English

English