Ports are vital hubs for global trade and logistics, where waterway depth and navigational safety directly impact economic efficiency and vessel operations. However, sediment and debris accumulation often reduce water depth, threatening port functionality. Dredging operations address this by removing bottom sediments, and dredging rubber self-floating hoses have emerged as a critical tool in port maintenance due to their unique design and superior performance. This article explores the technical advantages, application scenarios, real-world case studies, and future prospects of self-floating hoses in port maintenance.

Technical Advantages of Dredging Rubber Self-Floating Hoses

Designed for challenging aquatic environments, dredging rubber self-floating hoses offer distinct advantages that make them ideal for port maintenance:

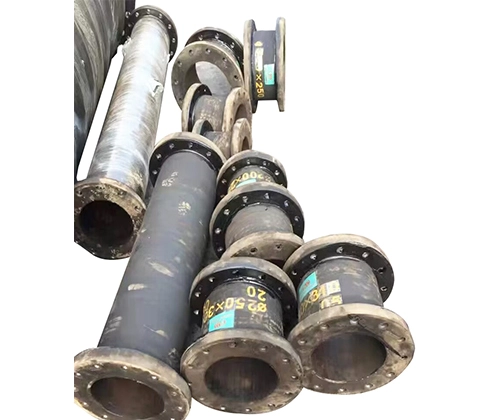

Self-Floating Capability:

Constructed with lightweight polymer materials and integrated buoyancy layers (e.g., closed-cell foam or air chambers), these hoses float on water without additional support equipment, reducing installation complexity and costs.

In port maintenance, self-floating hoses adapt to water level changes, maintaining optimal positioning and preventing sinking or entanglement due to currents or tides.

Superior Corrosion and Wear Resistance:

Port waters often contain salt, chemicals, and abrasive sediments. The inner layer of self-floating hoses, made with corundum-enhanced rubber, offers 3x the wear resistance of standard rubber, ensuring durability against abrasive slurries.

The outer layer features UV-resistant and seawater-corrosion-resistant compounds, providing a service life of over 5 years in harsh coastal environments.

High Strength and Flexibility:

The middle layer incorporates high-density steel wire braiding or fiber reinforcement, enabling the hose to withstand pressures up to 10 atmospheres, ideal for high-pressure sediment transport.

Its flexible design accommodates complex water currents and terrain, reducing the risk of fractures common in rigid pipelines.

Modular Design and Ease of Maintenance:

The modular construction allows quick connection and disassembly, adapting to varying pipeline lengths required in port dredging projects.

Advanced models feature embedded sensors (“smart hose” technology) to monitor wear and pressure in real-time, enabling predictive maintenance and minimizing downtime.

These technical strengths enhance operational efficiency, safety, and cost-effectiveness in port maintenance.

Application Scenarios in Port Maintenance

Dredging rubber self-floating hoses are versatile and widely used in the following port maintenance scenarios:

Channel Dredging:

Sediment accumulation in port channels can hinder large vessel navigation. Self-floating hoses, paired with dredging vessels, transport extracted sediments to designated disposal sites (e.g., offshore dumping grounds). Their buoyancy ensures stable positioning despite water currents.

Case Study: In Shanghai’s Yangshan Deep-Water Port maintenance project, self-floating hoses enabled the daily transport of 100,000 cubic meters of sediment, reducing project timelines by 20%.

Wharf Area Dredging:

Wharf zones, prone to sediment buildup from prolonged vessel docking, require precise dredging. Self-floating hoses can be deployed in confined waters, working with compact dredging equipment to restore berth depth.

Case Study: At a Tianjin Port wharf maintenance project, self-floating hoses operated flawlessly for 800 hours in turbulent waters, cutting pipeline replacement costs by 30%.

Environmental Protection and Pollutant Removal:

Beyond sediment, ports must address pollutants like debris or oil residues. The corrosion resistance and sealing properties of self-floating hoses make them suitable for transporting chemically contaminated mixtures without secondary pollution.

Smart hoses with real-time monitoring prevent leaks, safeguarding port ecosystems.

Emergency Dredging Systems:

In urgent scenarios, such as post-typhoon sediment surges, the rapid deployment of self-floating hoses is critical. Their modular design enables setup within hours, restoring port operations swiftly.

Real-World Case Study: Guangdong-Hong Kong-Macao Greater Bay Area

In a port maintenance project in the Guangdong-Hong Kong-Macao Greater Bay Area, self-floating rubber hoses demonstrated exceptional performance. The port’s navigational channel had shallowed from a designed 12 meters to under 9 meters due to sediment buildup, impeding container vessel access. A 5-kilometer self-floating hose system was deployed alongside a large cutter suction dredger. Key outcomes included:

High Efficiency: The hoses transported 150,000 cubic meters of sediment daily, improving efficiency by 25% compared to traditional rigid pipelines.

Operational Stability: The system remained stable in strong winds and waves, operating continuously for 1,000 hours without replacement.

Cost Savings: Compared to steel pipelines, the self-floating hose system reduced installation and maintenance costs by 40%.

Environmental Benefits: Smart hoses with wear-monitoring sensors prevented sediment leaks, protecting the surrounding marine ecosystem.

This case underscores the reliability and cost-effectiveness of self-floating hoses in complex port environments, setting a benchmark for future projects.

Future Prospects

As global port construction accelerates and environmental regulations tighten, the demand for dredging rubber self-floating hoses is set to grow. Future developments include:

Global Expansion:

With the Belt and Road Initiative driving port development, Chinese self-floating hoses are gaining traction in Southeast Asia, Africa, and South America. Streamlined supply chains and localized services will boost global competitiveness.

Conclusion

Dredging rubber self-floating hoses are transforming port maintenance by combining self-floating capability, durability, and smart technology. They enhance operational efficiency, ensure safety, and support environmental sustainability. Real-world successes, such as in the Greater Bay Area, highlight their reliability and economic benefits. As technology advances and global demand grows, these hoses will continue to serve as a “flexible force” in maintaining the vitality of ports worldwide.

Ready to elevate your port maintenance projects with high-performance dredging rubber self-floating hoses? Contact us for customized solutions tailored to your needs!

English

English